-

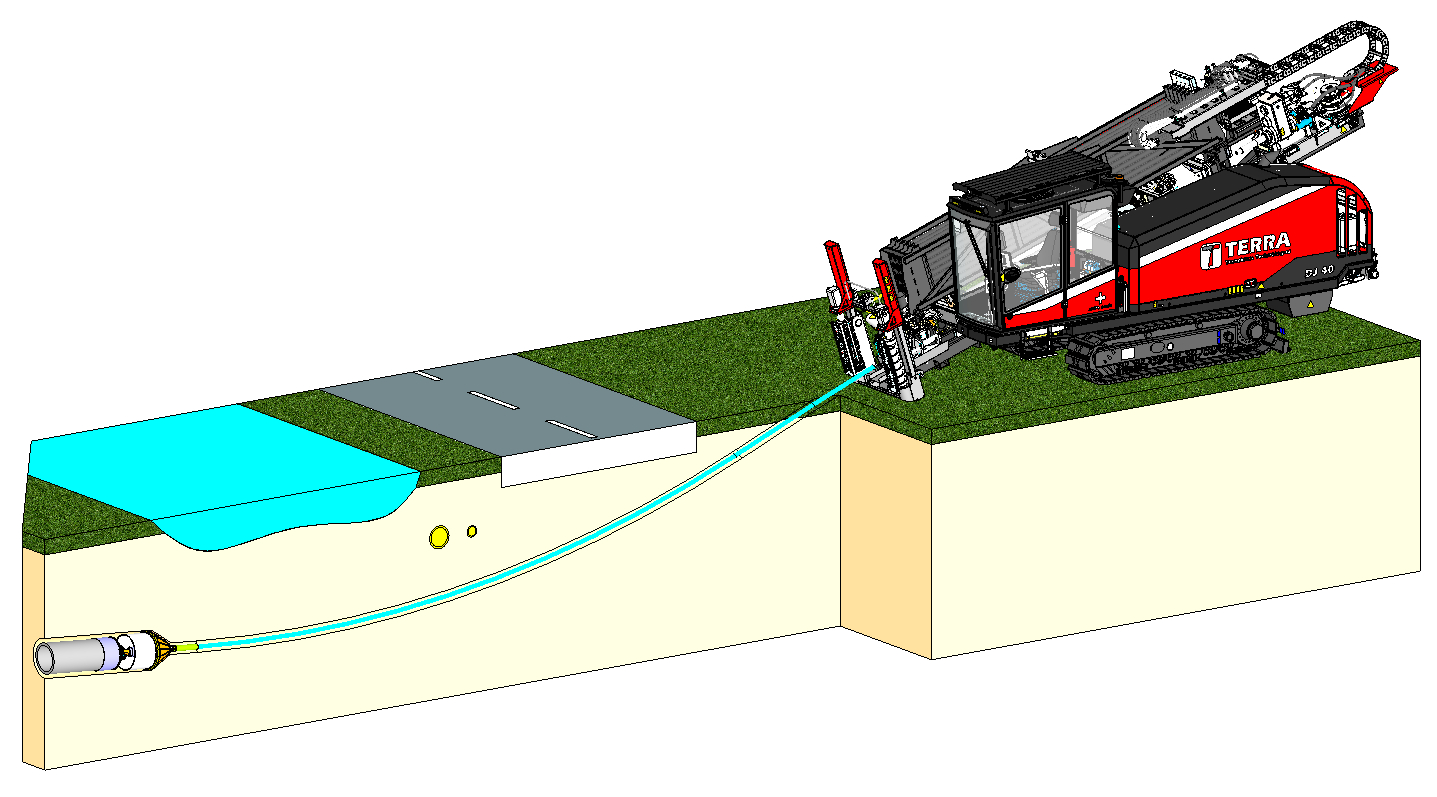

Equipado con un motor diésel HATZ de 75 HP (nivel 5), el TERRA-JET DJ 10 ofrece hasta 4,2 toneladas de potencia de tracción y empuje, así como 1.800 Nm. de par a plena rotación en la barra de perforación de 200 rpm. Con su reducido nivel de ruido y consumo de Diesel, el equipo es ideal para zonas urbanas con espacios reducidos. El equipo también tiene una pequeña huella de CO2 y un rápido tiempo de instalación.

-

deutsch |

english |

français |

español |

Jobs |

+41 62 749 10 10