Steered bores out of basement and pit - TERRA-JACK 125 steered bores out of basement and pit steered bores out of basement and pit TERRA-JACK 125 –

Versatile application The TERRA-JACK 125 allows pressing out of basements as well as from pit to pit. The only prerequisite is that undergrounds are displaceable. The tapered drill head combined with the thrust force allow to build steered bore paths. After pipe pulling on the first section underneath the driveway, the directional rod pusher was installed and fixed in the middle pit, from where the second section was pushed parallel to the driveway and underneath the garden. That saved existing plants in the garden from disturbance through trenching. It is the possibility of these two applications that makes the TERRA-JACK 125 the perfect trenchless system for house connections in displaceable underground.

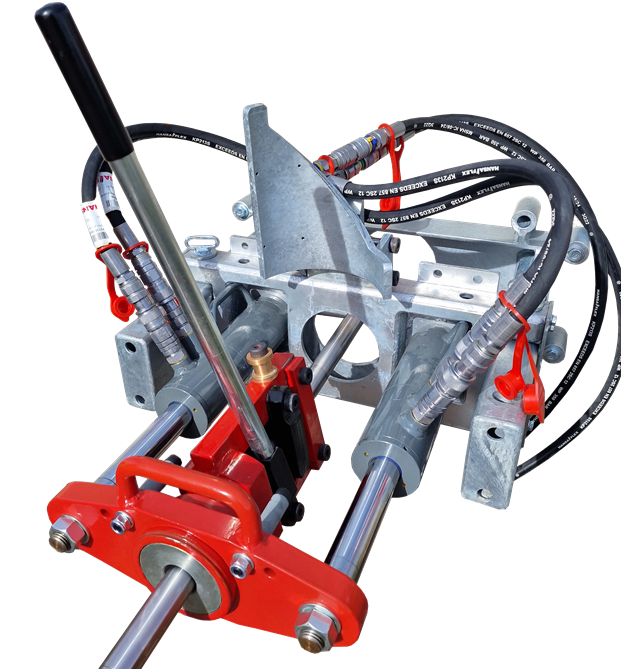

Steered press-bores A locating device such as DigiTrak Falcon F1 is used to track the bore and purposely reach steering radii up to 25 m (82 ft). For that purpose a transmitter is placed in a sonde-housing directly behind the drill head. This transmitter sends a signal through the underground to the receiver, where the bore can be tracked by the drilling team. Through rotation at the hand-operated lever on the TERRA-JACK the drill head is positioned in the desired orientation before pushing with the machine.

Pic 1: The TERRA-JACK in use of a laying of new electric lines under the yard access road and under the garden. Pic 2: Drill master pressing the steered pilot bore from the basement with the TERRA-JACK flanged to the wall. Pic 3: The TERRA-JACK is driven by a mini excavator. The hydraulic hoses are connected through the light well to the TERRA-JACK. Pic 4:TERRA-JACK base unit after pipe pulling and removal from the wall flange. Pic 5: The pilot bore reaches the middle-pit dead on target in the corner, leaving enough room for the subsequent installation of the TERRA-JACK. Pic 6: Pulling-in of a protective pipe outer diameter 92 mm (3.6”). Expanding of the bore channel and pipe pulling in one single step. Pic 7: The TERRA-JACK 125 pulls the expander cone with forces of up to 12.5 tonnes (27’000 lbs) through the ground. Here the expander cone with pipe is just arriving at the end of pipe pulling-in.